Blue Flame Burners

Blue Flame® Burners – Patented Technology Systems

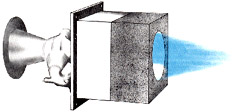

Burner Description and Operation

When starting from a cold condition, start-up oil enters the Oil Start-up Nozzle through Valve “A” and ignition is accomplished either directly by an air cooled spark plug or indirectly by a gas pilot which is ignited buy a spark plug. A standard ignition transformer is employed in either system.

At the same time air from a blower entering the Injector Nozzleand Venturi Mixing Tee creates a negative pressure inducting recirculation of combustion gases from the Flame Tunnel, through the Hot Gas Return Tube.

After approximately 45 seconds of operation, Valve “B” is opened permitting Run Oil to flow into the Hot Gas Return Tube where it is mixed with the recirculating combustion gases, immediately becoming gasified and transported to the mixing chamber. These recirculated combustion gases mix with and preheat the incoming combustion air, increasing combustion efficiency greatly.

The mixture of air, fuel and recirculated combustion gases passes to the Flame Tunnel where it is burned.

Valve “A” is then closed and burner is operating on gasified running oil.

The normal operating cycle is continuous until the flow of oil to the burner is interrupted.

Alternately the burner can be fired with gas, in which case the Return Tube is cooled by air from the blower. The BLUE FLAME Burner can also operate with any proportion of gas and oil simultaneously.

The BLUE FLAME Burner due to its unique capability of vaporizing its oil and preheating its combustion air, burns with a clean blue flame. This is accomplished with no moving burner parts. It was first introduced to the non-ferrous foundry industry and proved to be an instantaneous success. Today it is recognized that the BLUE FLAME Burner offers many advantages for an almost unlimited variety of industrial applications.

Blue Flame® Burners – Patented Technology Systems

- Heat Treating Furnace

- Forging Furnace

- Crucible Melting Furnace

- Reverberatory Furnace

- Salt Bath Hardening Furnace

- Annealing Furnace

- Billet Heating Furnace

- Vitreous Enameling Furnace

- Glass Melting Furnace

- Ceramic Kiln

- Boilers

- Rotary Kiln

- Paint Oven

- Coal Dryer

- Aggregate Dryer

- Incinerators

- Ladle Heaters

- After Burners

- Air Heaters

NOTE:

The BLUE FLAME Burner is protected by existing as well as pending patents. For more details on just what the BLUE FLAME concept of fuel combustion can mean to you, write or call us.